Gallery

Canam Manufactured Products (CMP) Inc. is a division of Canam Tool & Engineering Inc. Located just outside of Vancouver, BC in the Port Kells industrial area of Surrey, we are a full service CNC machining centre.

Industries We Serve

Manufacturing

Prototyping

Hydraulics

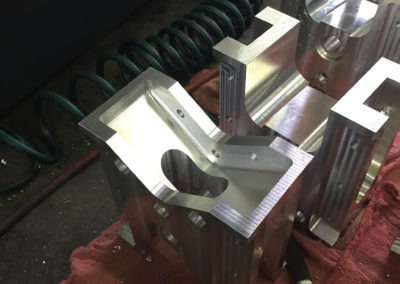

Tool and die

Electrical

Plastics

Amusement park rides

Hydrogen fuel cell technologies

Drilling rig repair

Our History

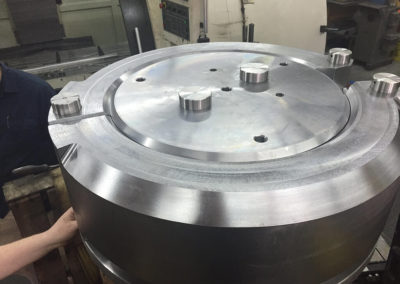

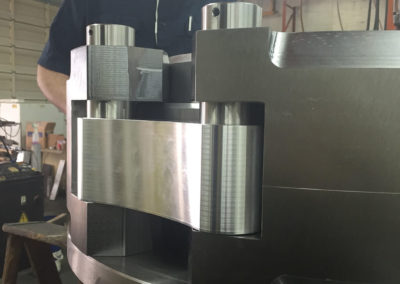

Canam Tool was incorporated as a custom machine shop in 1986 specializing in the manufacturing of long-line helicopter logging hooks, swivels, and shock absorbers. We have since grown to be a successful CNC machine shop specializing in short to medium production runs for worldwide manufacturing companies. Facilities include CNC mills and lathes, manual mills and lathes, welding and metal fabrication, heat treating, mold design & fabrication and other related manufacturing processes. See our capabilities page for more information.

In 2000 Canam formed a new division, CMP, to manufacture auxiliary equipment for the plastics industry. CMP acquired the assets and designs of Webb Technologies Ltd. a company that had developed and marketed the SPEEDRYER and AUTOHOPPER since 1991. This acquisition brings more than twenty years of experience in plastics drying and loading to a vertically integrated manufacturing and marketing operation. Over the past few years, we have also developed the Smartfill product line specifically for the machining industry to boost our product line.

We manufacture all CMP products completely in-house. When you buy from us it’s guaranteed 100% Canadian made and manufactured. To preserve the quality of our products, we ensure that the majority of purchased components we use are North American made.

CMP has the personnel and facilities to offer total customer support including parts and service, application evaluation, testing and technical advice.

Our Capabilities – CNC EQUIPMENT

CNC MILLING EQUIPMENT

| 2010 Morrison VMC 7833 | 78″ x 33″ x 30″ |

| 2006 FADAL VMC 6030 | 60″ x 30″ x 38″ |

| 2008 FADAL VMC 4525 | 45″ x 25″ x 31″ |

| 2006 FADAL VMC 4020 15k | 40″ x 20″ x 20″ |

| 2001 FADAL VMC 3016 | 30″ x 16″ x 20″ |

| 2012 MAG FADAL VMC 4020 | 40″ x 20″ x 31″ |

| 2012 Manford VMC 4020 10k | 40″ x 20″ x 30″ |

| 2014 Maxcut 4524 | 45″ x 24″ x 30″ |

| 2015 Maxcut 4524 | 45″ x 24″ x 30″ |

| 2001 OKUMA CADET VMC 4020 | 40″ x 20″ x 20″ |

| 2004 HAAS Tool Room Mill | 30″ x 15″ x 16″ |

CNC TURNING CENTERS

| 2014 Leadwell LTC 35 CXL | 26″ od, 21″ chuck, 80″ length, 7.50″ spindle bore. |

| 2013 OKUMA L400 CNC lathe | 12″ chuck, 40″ length, 3.05 spindle bore |

| 2014 OKUMA Genos CNC lathe | 8″ chuck, 17″ length, 2.05 spindle bore, live tooling |

| 2001 OKUMA L1060 CNC lathe | 12″ chuck, 17″ length, 2.75″ spindle bore |

| 2005 Yama Seiki GLS 150M | 6″ chuck, 17″ length, 2.0 spindle bore, live tooling |

CMM EQUIPMENT

| 2006 FARO Arm CMM |

MANUAL EQUIPMENT

| TOS Boring Mill | 30″ square table |

| Parsimaster Knee Mill | 32″ x 15″ x 20″ |

| Advance Lathe | 14″ od x 40″ length |

| Colchester Triumph 2000 lathe | 20″ swing x 48″ length |

OTHER EQUIPMENT

| 12″ x 36″ Brown & Sharp auto surface grinder |

| 8″ x 18″ Kent auto surface grinder |

| 6″ x 12″ Haarig surface grinder |

| Vertical band saw DoAll |

| Miller 250 MIG and 200 Syncrowave TIG welders |

| H frame hydraulic Press |

| Tumbling and Vibrating deburring machines |

| Amada Automatic saw |

| Heat treatment ovens (small capacity) |

| Darex bench grinders |

| Hardness Tester |

Contact Us

Canam Manufactured Products Inc.