Speedryer

Thermodynamic Hopper Dryer

The reliable one!

The SPEEDRYER is a thermodynamic hopper dryer that features the newest and best technology to dry plastic.

The SPEEDRYER makes it possible to change materials in half an hour or less.

Quick, efficient drying is achieved using a unique design that employs heat pipes to convey heat energy directly to the plastic pellets in the dryer. Rapid heat transfer quickly increases the vapor pressure in the pellet forcing entrapped moisture to the pellet surface. A counter flow of heated, sub-atmospheric pressure air conveys the moisture away from the plastic and out of the dryer. Drying power is equal to a desiccant dryer in 30 minutes or less.

- Easy to set up and use

- Minimal maintenance required

- Easy to clean

- Compact and light weight

- Mounts on feed throat

- Fully insulated epoxy composite hopper

- Energy efficient

The SPEEDRYER hopper is manufactured from a reinforced composite epoxy that is insulated to maintain the drying temperature with optimum efficiency. It is strong & durable, yet light weight and easy to clean. The interior of the dryer is corrosion free aluminum and stainless steel. A top lid with captive thumb screws permits disassembly without additional tools. The easy to use controller features full PID temperature control with settable high and low alarms. Indicators are provided to show heater and fan functions.

Method of Operation

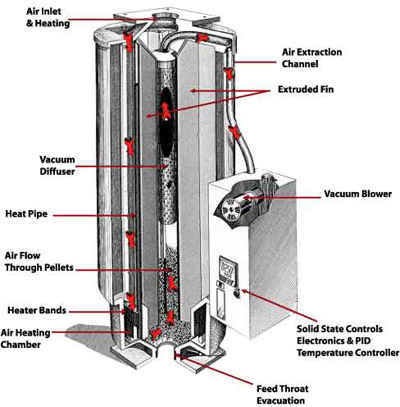

The SPEEDRYER uses the rapid application of heat to increase the vapor pressure inside plastic pellets and to force entrapped moisture to the pellet surface. A counter flow of heated air strips the moisture from the pellet and transports it away to the atmosphere leaving dry plastic. The interior of the dryer is comprised of a series of radially oriented vertical aluminum fins. Inside each fin, from bottom to top is a heatpipe. The heatpipe extends into the base of the dryer where it is heated by conventional electric heater bands. The heatpipe quickly becomes isothermal and transfers it’s latent heat energy into the vertical fin powering the fin to a uniform temperature along it’s length. (see heatpipe theory below)

The vertical fins are shaped and situated in such a way as to maximize radiant and conductive heat transfer to the plastic pellets. The result is much faster heating of the pellets than by the use of circulating hot air which is not an efficient heat conductor. Since the fins in the SPEEDRYER are the same temperature top to bottom, plastic becomes heated as soon as it enters the top of the dryer, unlike a desiccant or hot air dryer that has a significant temperature gradient through the hopper.

Ambient air is drawn in by a vacuum motor through restricted inlets at the top of the dryer. It is transferred through a channel in each of the fins adjacent to the heatpipes where it is heated. The air is extracted through the bed of plastic pellets by the vacuum diffuser, stripping off the moisture which is then exhausted from the dryer.

The vacuum motor also connects with an annular opening in the base of the dryer. This extracts any gases or vapors generated in the rear zone of the molding machine screw/barrel. The result of this technology, dries plastic in 30 minutes with low energy consumption, no desiccant or dew point to monitor and only one moving part. The SPEEDRYER offers excellent drying of most hygroscopic plastic materials, especially nylons and high temperature resins such as; PC, PET, PEI, PSU, PBT and LCP.

CMP Heatpipe Operation (thermosyphon)

Heater bands are employed to heat the base of the heat pipe. The interior of the pipe is a vacuum. The heat vaporizes fluid in the pipe and forces the vapors through the length of the pipe. As the vapor encounters a cooler portion of the pipe it condenses and releases the heat energy. Gravity returns the condensate to the vaporizing zone and the cycle repeats continually in the closed loop system. Within minutes, the entire heat pipe becomes isothermal. In practice, the pipe has a temperature variation of less than 1 degree F. top to bottom.

Dryer Specs

| SPEEDRYER | SD1500 | SD2000 |

| Height | 24″ | 29″ |

| Diameter | 10″ | 10″ |

| Width (including control cabinet) | 15″ | 15″ |

| Weight | 40 lbs | 50 lbs |

| Capacity | 0.5 cu/ft | 0.8 cu/ft |

| Power | 1.5 KW | 2.0 KW |

| Voltage | 240 VAC | 240 VAC |

| Base | 6″X 6″ | 6″X 6″ |

Speedryer Throughput & Temperature Guide

| MATERIAL | TEMP | TEMP | Maximum Suggested Throughputs | ||

| Range °F | Range °C | SD1500 lb/kg per hr |

SD2000 lb/kg per hr |

SD TWIN | |

| ABS | 190 – 220 | 88 – 105 | 20/09 | 30/14 | 60/28 |

| ABS/PC | 225 – 275 | 106 – 135 | 30/14 | 40/18 | 80/36 |

| ACETAL | 220 – 250 | 105 – 122 | 40/18 | 60/27 | 120/54 |

| ACRYLIC | 190 – 225 | 88 – 106 | 25/11 | 35/16 | 70/32 |

| ASA | 190 – 220 | 88 – 105 | 25/11 | 30/14 | 60/28 |

| PA (NYLON) | 225 – 325 | 106 – 163 | 40/18 | 60/27 | 120/54 |

| PBT | 225 – 350 | 106 – 177 | 30/14 | 40/18 | 80/36 |

| PC | 225 – 300 | 106 – 149 | 30/14 | 50/23 | 100/46 |

| PEI (ULTEM) | 275 – 375 | 135 – 191 | 30/14 | 50/23 | 100/46 |

| PEEK | 275 – 350 | 135 – 177 | 15/07 | 20/09 | 40/18 |

| PET | 225 – 350 | 107 – 177 | 15/07 | 20/09 | 40/18 |

| PPO (NORYL) | 220 – 250 | 105 – 122 | 35/16 | 50/23 | 100/46 |

| PSU | 250 – 375 | 122 – 191 | 30/14 | 50/23 | 100/46 |

| PUR | 200 – 230 | 94 – 108 | 25/11 | 35/16 | 70/32 |

| PVC | 180 – 220 | 82 – 105 | 40/18 | 60/27 | 120/54 |

| SAN | 190 – 220 | 88 – 105 | 20/09 | 30/14 | 60/28 |

| TPE/TPU | 190 – 240 | 88 – 116 | 15/07 | 25/11 | 50/22 |

DIMENSIONS & TECHNICAL DATA

| SD1500 | SD2000 | SD TWIN | |

| Height (in/cm) | 25/64 | 30/77 | 49/117 |

| Depth (in/cm) | 10/26 | 10/26 | 16/41 |

| Width (in/cm) | 15.5/40 | 15.5/40 | 22/56 |

| Weight(lb/kg) | 45/20.5 | 55/25 | 120/55 |

| Voltage | 240 / 1PH | 240 / 1PH | 240 / 1PH |

| KW | 1.5 | 2.0 | 4.0 |

| Max temperature °F/°C | 425/200 | 425/200 | 425/200 |

| Hopper Capacity (lb/kg of PA) | 14/6.5 | 18/8.2 | 36/16.4 |

Other Products

AutoFill

Not So Smartfill

Contact Us

Canam Manufactured Products Inc.